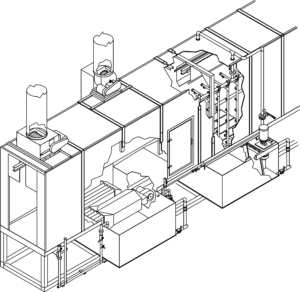

Custom Industrial Finishing Systems—Designed, Built & Automated Under One Roof

End‑to‑End Powder‑Coat & Paint Lines Engineered for Maximum Throughput and Uptime

About GAT Systems

A History of Forward Thinking, Satisfied Clients and Long-Term Employees

Born out of engineering expertise and passion for efficient design, GAT was founded by the current owner’s grandfather in 1958 in St. Louis, Missouri.

From the beginning, we put our focus on creating custom finishing solutions and process lines for companies in North America.

GAT was at the forefront of industry change in the 1960s, innovating and creating patented technology and processes.

We’ve always had a strong focus on family and our employees, which is why people come to work for GAT and stay here for many years.

Why Should You Choose GAT Systems?

When is it time to stop outsourcing and build an in-house automated finishing system?

It starts with knowing how much you currently spend and how much throughput volume you may need in the future. Many manufacturers outsource some to all of their finishing, be it powder coating or liquid finishing, because they want to leave it up to “experts”.

Don’t think you have the space for a Custom Finishing System? The GAT Systems engineering team would like to help you run the numbers. “If there’s a better way to do it – the GAT engineering team is ready to earn the opportunity to help you define and validate it”.

The GAT Process for Custom Finishing Systems – your requirements assessment is designed to help “right-size” a finishing process by taking the production volume and physical dimensions of parts to be coated and calculating a conveyor line speed to meet these requirements. The goal here is to determine the total annual conveyor length necessary to process the volume of production parts for the target production goal, including future growth.

The GAT Systems relationship starts with our team investing in the required discovery with you, calculating answers to these questions by performing the GAT analysis of process specific information. Each of these analyses are discussed in the following sections.

If you’re considering the purchase of a batch oven, use the calculator below to determine which GAT batch oven is right for your needs.

GAT SYSTEM PRODUCTS

Every component is engineered, fabricated and tested in our Fenton, MO facility.

The washer that will save you money and decrease downtime during production

Polypropylene is the difference maker when it comes to washers. Whether it’s a batch washer, industrial washer, parts washer, mesh belt washer, or barrel washer, your best bet is starting with GAT’s PolyPro washer.

What It Does

Multi‑stage pretreatment cleaning

Why It’s Better

Chemical‑proof housings, 10‑year anti‑corrosion warranty

The perfect solution for wet paint or powder coat needs

Our GAT Batch Ovens feature a max operating temperature and are factory pre-fired and tested. Standard delivery takes 6-8 weeks and can be expedited.

What It Does

Flexible cart‑loaded curing

Why It’s Better

Pre‑fired at factory, 150–500 °F operating range

Whether you need powder coating, wet paint, or low-temperature curing, we have the right process oven for you.

Our General Automatic Transfer team streamlined our production of process ovens to include six-inch-thick insulated oven panels, high-velocity air seals, floor-mounted ductwork, and FM, UL, and NFPA-compliant gas train utilized on the gas-fired heaters.

What It Does

Continuous‑flow curing (convection & IR)

Why It’s Better

6″ insulated panels, patented air‑seal, NFPA‑compliant gas trains

Focus on efficient movement and optimal layouts

From overhead conveyors (which comprises about 90% of our work) to mesh belt, chain and crossbar, wicket, drum and batch conveyors, GAT can design and install a solution that works perfectly for your company.

What It Does

Move parts through the line

Why It’s Better

Overhead, power‑and‑free, mesh‑belt, wicket & more, all PLC‑controlled

Cost-effective insulated powder enclosures that maximize your system performance.

GAT Powder Coating Rooms are designed to fulfill your specific job requirements, including environment-controlled powder storage areas.

GAT understands the importance of maintaining a clean, climate controlled powder coating area for spray coating applications.

What It Does

Clean, climate‑controlled spray environment

Why It’s Better

Modular enclosures sized to your booth & reclaim goals

Why Manufacturers Choose GAT

Fully Custom, Never Cookie‑Cutter

Right‑sized for your takt time, footprint and finish spec.

Lowest Total Cost of Ownership

Energy‑efficient ovens and corrosion‑proof washers cut operating spend.

Patented Technology

From air‑seal ovens to polypropylene washers, we solve problems others ignore.

Real ROI Calculators

Know your payback before you buy with our online tools.

Remote Support & Fast Parts

PLC access and in‑stock spares keep you running.

Single‑Source Accountability

One partner from design to daily production.

Let’s talk about how GAT can impact your business.

BLOG, NEWS & UPCOMING EVENTS

Curing and Drying Ovens How Temperature Uniformity Impacts Film Performance

When you’re making films, the ovens you use for curing and drying really matter. It’s not just about getting things dry; it’s about how the

Made in Missouri How Our Fenton Facility Controls Quality from Steel to Startup

You know, it’s pretty cool to think about how things are made, especially when it’s right here in our own backyard. Our facility in Fenton,

Manufacturing Efficiency Case Study 40 % Cycle-Time Gain with Direct-Impingement Ovens

So, we’re talking about manufacturing efficiency, specifically how to speed things up. A big part of that is the equipment you use, and ovens are

GAT Systems new website launch

GAT Systems, a leading provider of Finishing Systems, today announced the launch of its newly redesigned website. The modernized platform boasts a sleek, intuitive design,