Santa Rosa Systems

Exponentially Increasing Throughput with GAT

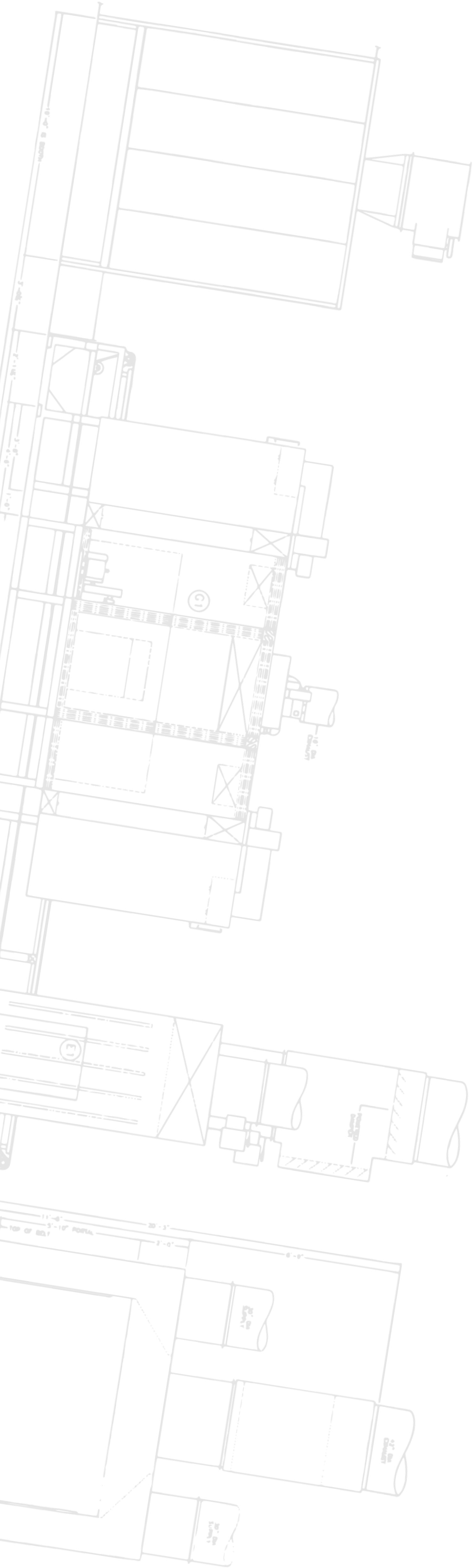

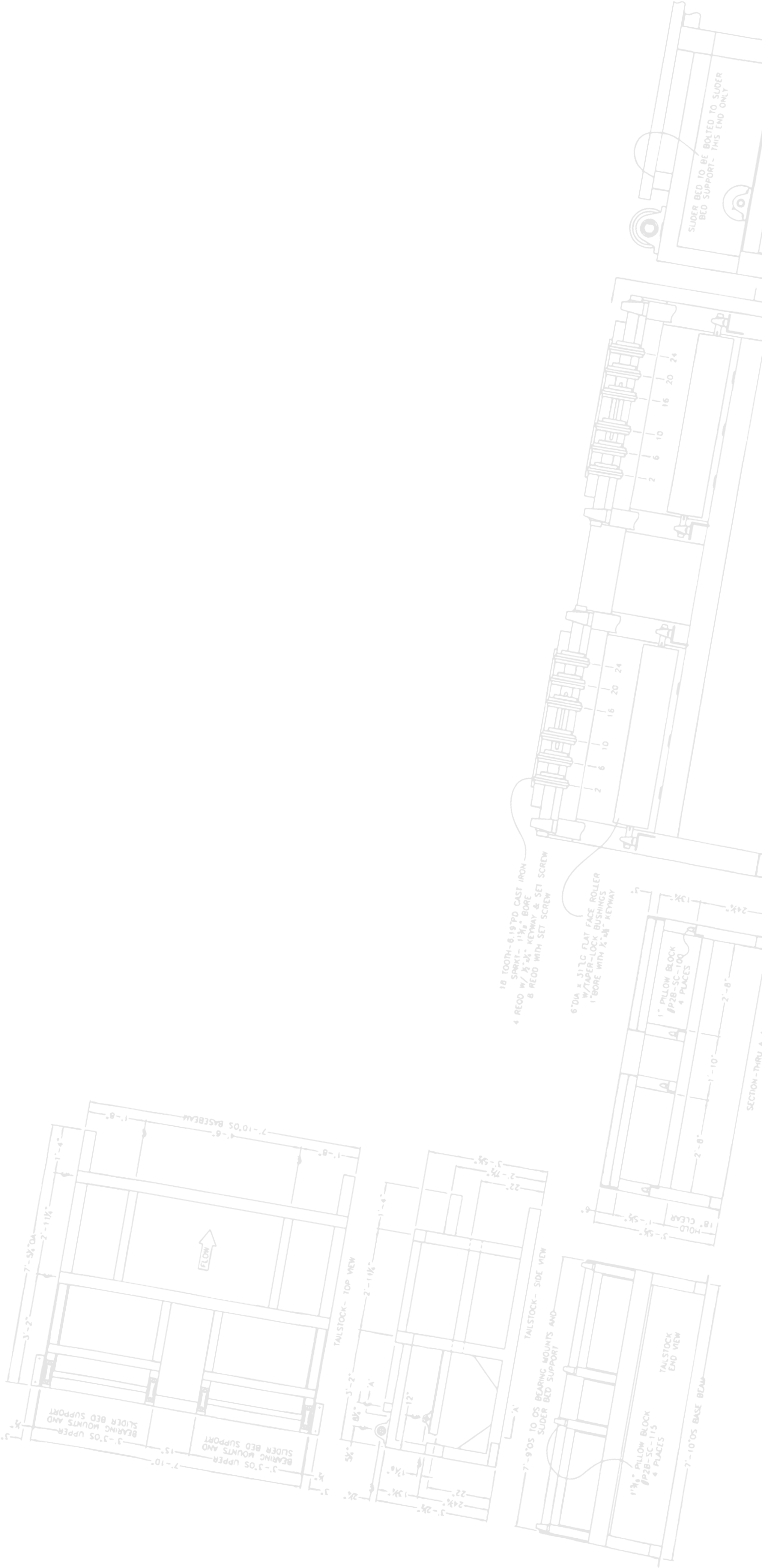

The ability to improve throughput in production means the difference between meeting or exceeding quotas and losing customers to their competition. To meet the ever-increasing demand for their products, Santa Rosa Systems partnered with GAT to increase their line density with improved hanging methods and other process improvements.

Concurrent with the implementation of the powder line, SRS improved vendor and supplier management, and a constructed a new state-of-the-art manufacturing and assembly facility. Santa Rosa’s new factory is nearly 100% operational. The collaboration between SRS and GAT resulted in a designed a finishing system that has improved throughput by 300% and improved the quality of the process and finish.

“The new line has given us the ability to blow our old system’s throughput out of the water. Every day, we paint the equivalent of 6 to 7 daily shifts worth of parts compared to our old powder paint system thanks to the line that we designed with GAT. The increase in efficiency has been outstanding and has made our customers very happy.” —Santa Rosa Systems