Infrared Process Ovens—Instant Heat, Compact Footprint, Lower Energy Use

When your finishing line demands rapid ramp rates or targeted heat zones, GAT’s infrared (IR) process ovens deliver. From electric short‑wave boosters to full gas catalytic cure tunnels, our modular IR systems integrate seamlessly with existing conveyors or stand alone for cell‑based production.

Why Choose a GAT Infrared Oven?

| Advantage | Engineering Detail | Production Payoff |

|---|---|---|

| Near‑Instant Heat‑Up | Elements reach setpoint in < 60 sec | Slash idle energy & increase line availability |

| Compact Length | 50–70 % shorter than convection ovens | Fits tight floors, boosts takt without expansion |

| Zoned Control | Individually PID‑controlled emitter banks | Fine‑tune heat to part mass & coating thickness |

| Energy Efficiency | 95 % radiant efficiency on catalytic models | Up to 40 % gas savings vs. convection |

| Clean, Silent Operation | No fans or recirc blowers on catalytic IR | Lower noise & zero cross‑contamination |

| Tool‑Free Access | Lift‑off panels for element change in minutes | Minimized downtime & maintenance cost |

IR Oven Series & Typical Applications

| Series | Heat Source | Peak Wavelength | Max Part Temp | Module Length | Ideal Uses |

|---|---|---|---|---|---|

| IR‑E‑SW | Electric quartz short‑wave | 0.8–1.2 µm | 650 °F | 4 ft | Powder pre‑gel, metallic basecoats |

| IR‑E‑MW | Electric medium‑wave ceramic | 2–4 µm | 550 °F | 6 ft | Wet‑paint flash‑off, plastic substrates |

| IR‑GC | Gas catalytic emitter | 3–6 µm | 500 °F | 8 ft | Full cure of bulky steel, energy‑sensitive lines |

| IR‑HYB | IR boost + convection finisher | Dual | 600 °F / 500 °F | 12 ft | Thick‑section castings, mixed loads |

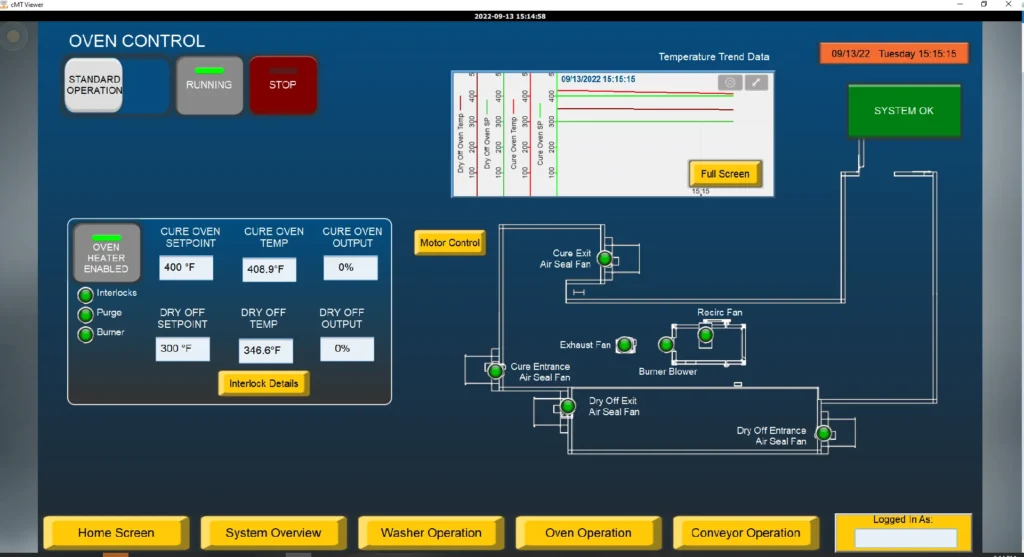

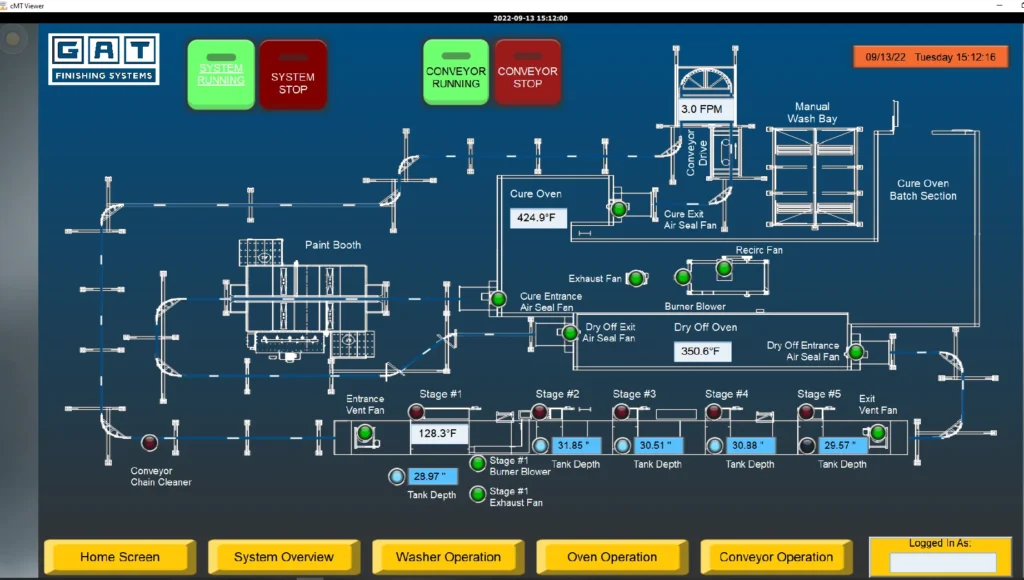

PLC, Smart Controls & Safety

Auto start and shutdown

Calendar and time basis with operator acknowledgement required.

Auto pump on/off with conveyor operation

Sync conveyor movement with pump operation as well as sequential pump start to lower power in rush.

Sequenced startup and shutdown capability

Pre-program your equipment to auto-start and shut down after certain tasks have been completed.

Remote monitoring & troubleshooting

Productivity Analysis

Productivity analysis charts show the percentage of time your conveyor has been running each day, and who was controlling the starts and stops.

Fault Log

Active fault logging and password protection to improve security and improve preventative maintenance.

Proven Performance Metrics

- < 2‑minute powder flow at 375 °F on 11‑ga plate with IR‑E‑SW series.

- 30–40 % fuel reduction recorded after replacing 40‑ft convection cure with 16‑ft IR‑GC tunnel.

- ±5 °F uniformity across 60‑in. belt verified on 9‑point SAT.

Integrate With Your Finishing Line

Infrared ovens bolt directly to GAT polypropylene washers, powder coating rooms, and enclosed‑track conveyors—or retrofit into third‑party systems for efficiency upgrades.

Frequently Asked Questions

Can IR ovens replace my entire convection cure?

Often yes—gas catalytic IR achieves full crosslink on most polyesters and urethanes. Hybrid combos available for heavy steel.

Are electric IR elements expensive to run?

Because elements duty‑cycle only when parts are present, total kWh is typically lower than a continually fired convection oven.

How often do elements need replacement?

Quartz SW elements average 12,000 hrs; catalytic pads 20,000+ hrs. Both swap in < 15 min.