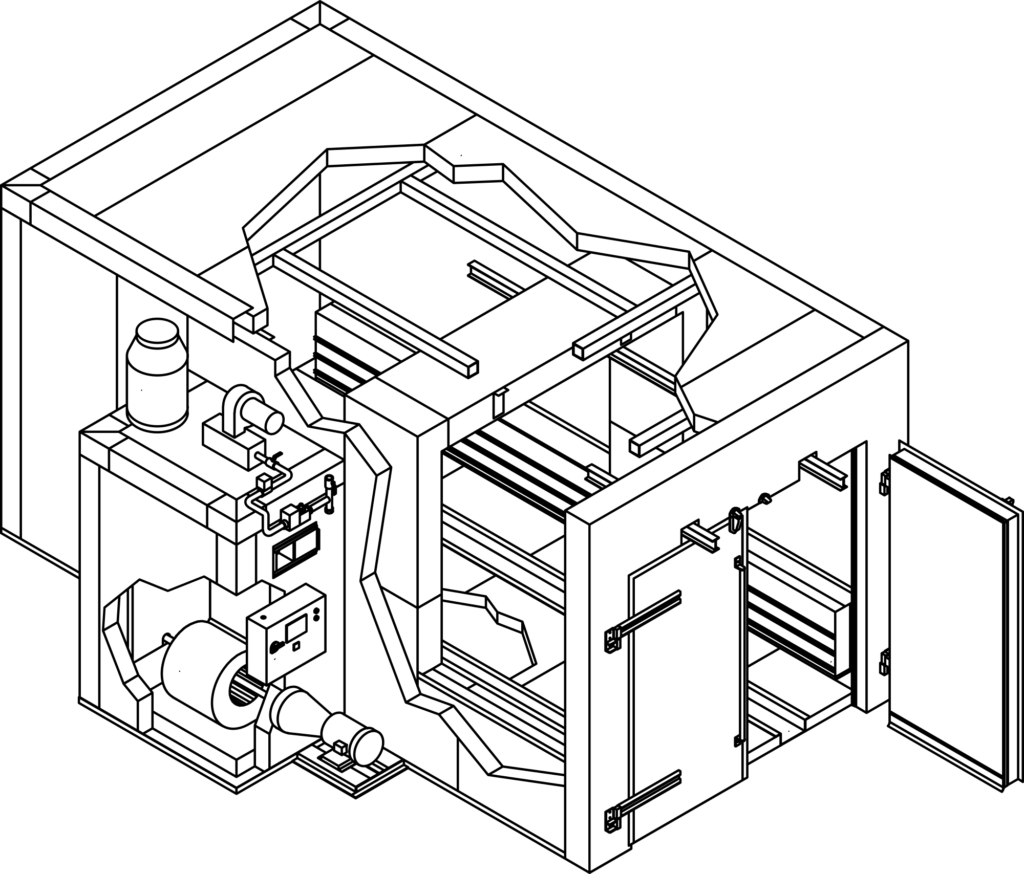

Batch Ovens—Flexible, Heavy‑Duty Curing for Powder & Liquid Finishes

When your production mix demands versatility, GAT’s industrial batch ovens deliver uniform cure profiles for everything from small weldments to 25‑ft structural frames—without the footprint of a conveyor line.

Why Choose a GAT Batch Oven?

| Advantage | Engineering Detail | User Benefit |

|---|---|---|

| Rugged Construction | 18-gauge aluminized steel, 6-in. mineral-wool insulation, 2,000 °F ceramic seals | Decades of service in harsh powder shops |

| Wide Temp Range | 150–500 °F standard; 650 °F high-temp option | Cure polyesters, hybrids, epoxies, urethanes & wet paint |

| Direct-Impingement Airflow | Top & side plenums with adjustable louvers | < ±5 °F temp uniformity, faster ramp times |

| NFPA-Compliant Gas Trains | Maxon burners, leak-test valves, flame supervision | Meets OSHA & insurance requirements out of the crate |

| Modular Panel Design | 12-in. tongue-and-groove sections | Expand length or height as product mix evolves |

| Quick-Ship Models | 6×6×8 ft to 10×10×20 ft standard | Install & cure parts in as little as 6 weeks |

The GAT Difference

Made of 18 ga. galv. steel and 4 lb. density mineral wool, these panels lower operating costs, up to standard and offer better working conditions around the oven

Allows for mounting C/P on the heater with virtually no field wiring (lowers cost and risk; no need for electrician)

Our vented door design effectively dissipates heat

Uniform airflow and temperature via dual duct design

Wider than competitor panels with 45% fewer seams, which increases efficiency

Grows along with your needs

Saves you time and money

During the first year of ownership GAT will make sure that everything was installed and built correctly

Features & Benefits

- Proportional Gas Control with Butterfly Valve

- High efficiency motor

- Adjustable high air recirculation rate

- 12” diameter exhaust stack

- 800,000-1.6 MBTU Eclipse Air Heat Burner

- Design operating temperature 150-500 degrees

- Dual Use – Wet Paint or Power Coating

- Fully assembled panels

- Insulated cart floor

- Top, side or rear mount heater location

- Numerous Conveyor Slots

- Provides for even temperature control

- Green; lower electrical demand

- Allows for wet and powder use

- Lowers install cost

- Wide range of BTU capabilities

- Wide range of operating capabilities

- Versatility

- Reduced installment man hours

- Optional – flexible

Standard & Custom Sizes

- 6′ x 6′

- 8′ x 8′

- 10′ x 10′

- 10′ x 8′

- 8′ x 10′

- 10′ x 12′

- 10′

- 14′

- 18′

- 22′

- 26′

- 30′

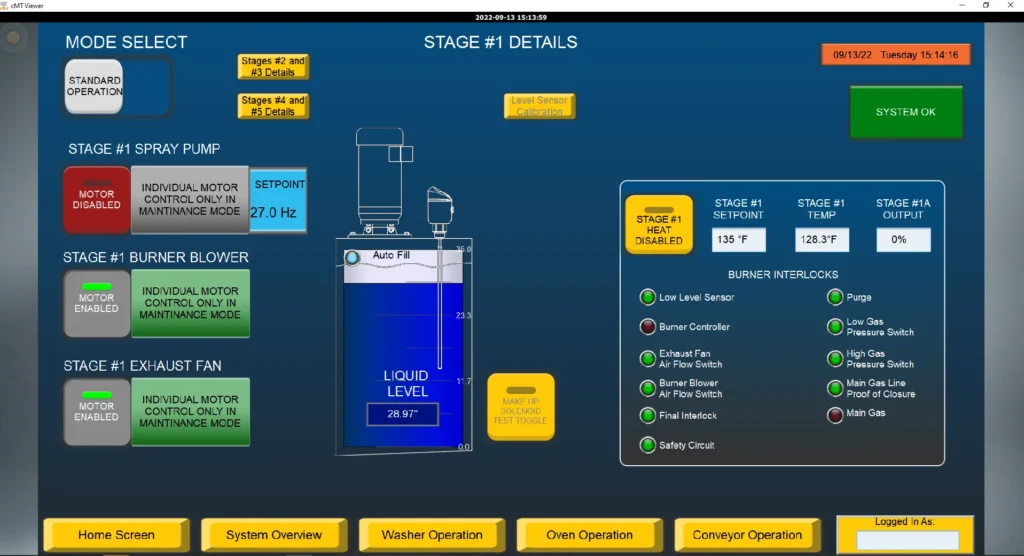

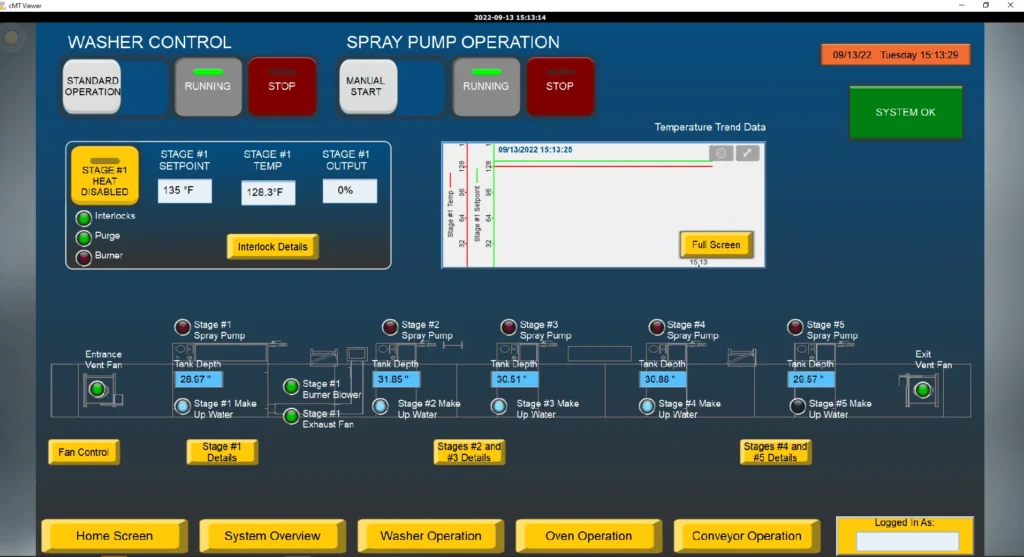

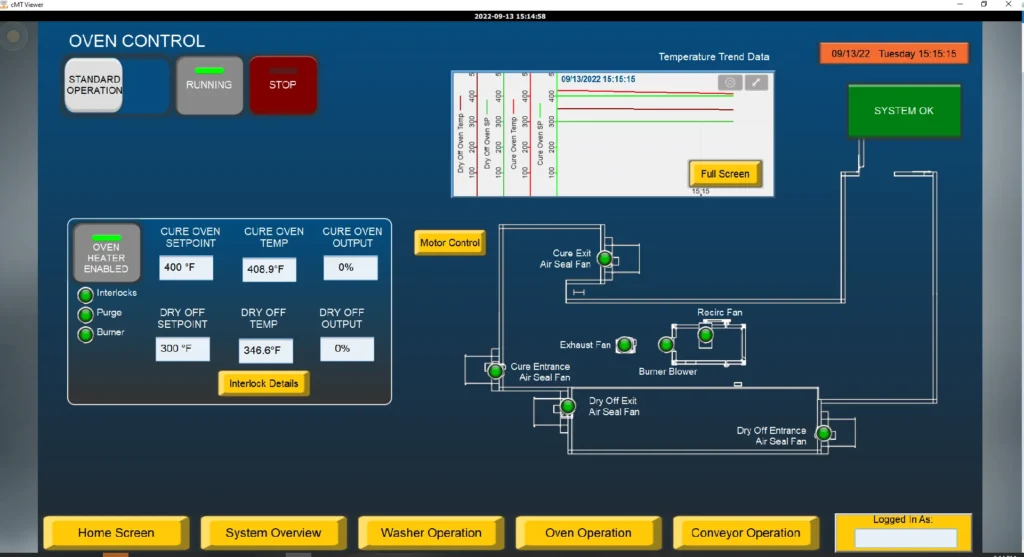

Smart Controls & Safety Features

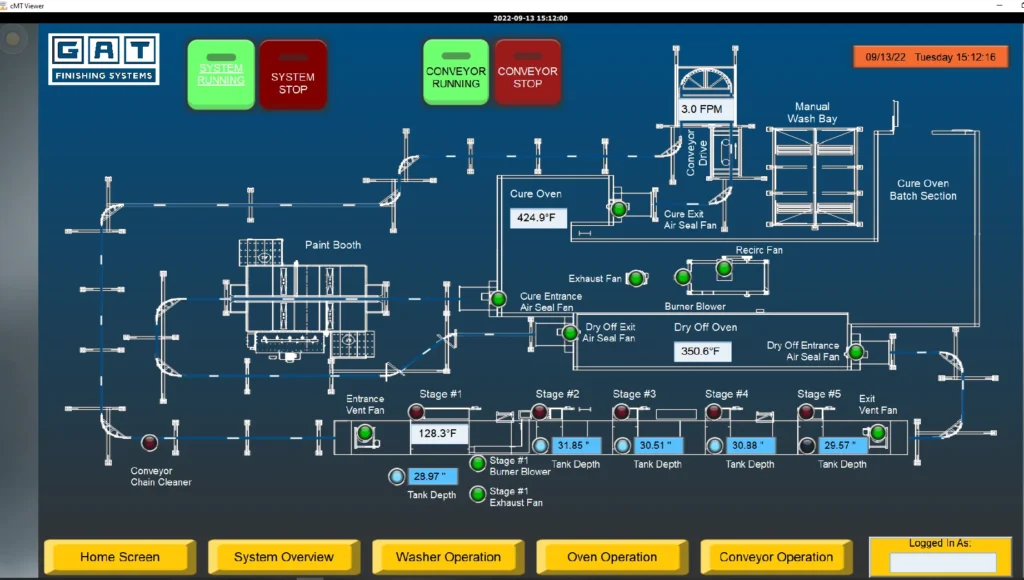

Touch‑Screen HMI

Recipe recall, trending charts, maintenance alerts.

Ramp‑Hold Profiles

Up to 20 segments for complex cure cycles.

Auto Cool‑Down & Exhaust

Controlled purge meets NFPA 86 Class A.

Remote VPN Access

GAT engineers diagnose heat curves in minutes.

Fire Suppression Ready

Interlocks for dry‑chem or water‑mist systems.

Performance Metrics Proven in the Field

- ±5 °F uniformity verified on 9‑point SAT test.

- 15–18 min rise to 400 °F on B‑8812 model (loaded).

- > 98 % uptime on PM‑plan customers.

Integrate With Your Workflow

Batch ovens pair seamlessly with GAT polypropylene washers, powder coating rooms and overhead conveyors for a phased approach to full finishing automation.

Frequently Asked Questions

Can the oven run wet paint & powder?

Yes—simply program separate ramp‑hold recipes for each coating.

What power & gas are required?

Standard models: 480 V / 3‑phase / 60 Hz, natural gas 2–5 psi; other utilities on request.

How do you ship large ovens?

Panels knock down to skid-size; reassemble with cam‑lock hardware – no welding.