So, we’re talking about manufacturing efficiency, specifically how to speed things up. A big part of that is the equipment you use, and ovens are a huge factor in finishing lines. This article dives into how using direct-impingement ovens can really make a difference, cutting down on how long it takes to get parts done. We’ll look at why they’re faster, how they compare to other types of ovens, and what you should think about when picking one for your shop. It’s all about getting more done, better.

Key Takeaways

- Direct-impingement ovens use high-velocity hot air jets to heat parts faster, which can significantly cut down processing time compared to standard convection ovens.

- These ovens are great for high-speed production lines and can help reduce color variation when curing mixed-metal parts due to their rapid heating capabilities.

- While infrared (IR) ovens are shorter and can be energy efficient, direct-impingement offers a strong balance of speed, versatility, and cost, especially when compared to standard convection.

- When choosing an oven, consider your specific parts, the coatings you use, your line speed needs, and the available factory space to make the best decision.

- Continuous ovens, including those using direct-impingement technology, generally offer higher throughput and more consistent results for high-volume production than batch ovens.

Understanding Direct-Impingement Ovens

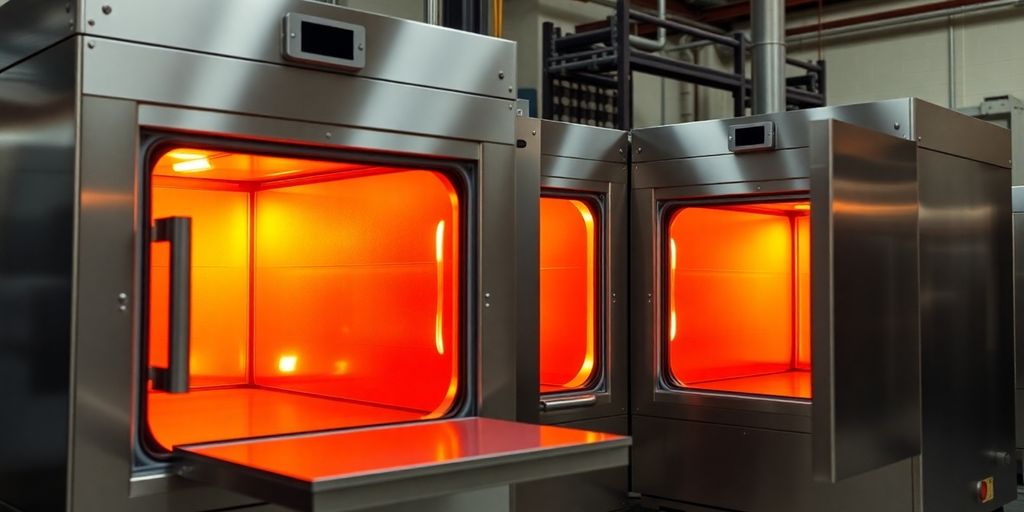

Direct-impingement ovens are a step up from standard convection, often called the “turbo” version. Instead of just circulating hot air, these ovens blast heated air directly onto the part’s surface from high-velocity jets positioned above and below the conveyor. This intense airflow means the heat gets to the part much faster.

The “Turbo” Convection Advantage

This direct blast of hot air is what gives these ovens their speed. It significantly cuts down the time needed to get parts up to curing temperature. Think of it like using a powerful hairdryer versus a gentle fan – the hairdryer gets things dry much quicker. This rapid heating is a big deal for production lines that need to move fast.

Key Engineering Details for Enhanced Performance

What makes these ovens tick? Well, they use special high-velocity plenums that are strategically placed over and under the conveyor belt. This setup is engineered to force heated air directly onto the product. Another neat feature is the use of patented Air-Seal vestibules, which create counter-flow curtains. These help keep the heat inside the oven and the cooler air out, which can lead to about a 15% gas saving and cooler working aisles. The ovens themselves are typically built with 6-inch mineral-wool panels that fit together like puzzle pieces, helping to maintain a consistent temperature inside, usually within ±5°F across the belt.

Ideal Applications for Direct-Impingement Technology

So, when should you consider this type of oven? They really shine in a few specific situations:

- High Line Speeds: If your production line is moving really fast, like over 75 feet per minute, direct-impingement can keep up.

- Mixed-Metal Loads: When you’re curing parts made of different metals, which can heat up at different rates, the rapid and even heating from impingement helps prevent color shifts.

- Cost-Conscious Facilities: If your facility can handle venting combustion products and you’re looking for a lower initial cost compared to full infrared systems, direct-impingement is a good middle ground.

These ovens are a solid choice when you need speed and efficiency without necessarily going for the most expensive, high-tech solution. They offer a tangible boost in performance for many common finishing applications.

Achieving Significant Cycle-Time Gains

When we talk about manufacturing efficiency, cutting down the time it takes to get a product through the oven is a big deal. Direct-impingement ovens really shine here, especially when you need to move things along quickly. They’re designed to blast hot air directly onto the part’s surface, which means faster heating and, you guessed it, faster curing. This isn’t just about making things go faster for the sake of it; it directly impacts your throughput and how much you can produce in a given time.

Maximizing Throughput with High Line Speeds

One of the main ways direct-impingement ovens boost efficiency is by allowing for much higher line speeds. Think about it: if your oven can heat and cure parts faster, the conveyor belt can move quicker. This means more parts pass through the oven in the same amount of time. For operations that are pushing for maximum output, this is a game-changer. It’s not uncommon to see significant gains in the number of parts processed per hour just by switching to this technology. We’re talking about potentially increasing your production capacity without needing more floor space or a bigger footprint.

Minimizing Color Shift in Mixed-Metal Loads

Dealing with different types of metal parts on the same line can be tricky. Some metals heat up faster than others, and if your oven isn’t precise, you can end up with color variations or uneven curing. Direct-impingement ovens, with their ability to deliver rapid and consistent heat, are particularly good at handling these mixed loads. The targeted airflow helps to equalize the temperature across different materials, reducing the chances of color shift. This consistency is key for maintaining product quality, especially when you’re running different parts back-to-back. It means less waste and fewer rejected parts, which also contributes to overall cycle-time efficiency.

Reducing Oven Length for Increased Efficiency

Because direct-impingement ovens heat so effectively and quickly, they often don’t need to be as long as traditional convection ovens. A shorter oven means a smaller footprint, which is a big plus if you’re working with limited factory space. But it’s not just about saving space; a shorter oven can also mean less energy consumption and faster ramp-up times. When you can achieve the same or better curing results in a shorter, more compact unit, you’re inherently making your process more efficient. This reduction in physical size and improved heating dynamics directly contribute to faster overall cycle times and better manufacturing efficiency.

The ability of direct-impingement technology to transfer heat rapidly and uniformly is the core reason for its cycle-time advantage. This isn’t just about speed; it’s about achieving the desired cure profile more effectively, which in turn allows for higher throughput and better resource utilization.

Comparing Curing Technologies

When you’re looking at different ways to cure coatings, it’s not a one-size-fits-all situation. Each method has its own strengths and weaknesses, and what works for one shop might not be the best fit for another. Let’s break down a few common types.

Direct-Impingement Versus Standard Convection

Think of direct-impingement ovens as the souped-up version of standard convection. While both use heated air, direct-impingement blasts that air directly at the part surface with high velocity. This means faster heating, which can lead to shorter oven lengths and higher line speeds. Standard convection, on the other hand, relies on circulating heated air. It’s a reliable workhorse, often better suited for heavier parts or when you need a gentler heating gradient, like with certain liquid paints. However, this gentler approach usually means a longer oven is needed to achieve the same cure time, taking up more floor space.

| Feature | Direct-Impingement | Standard Convection |

| Airflow | High-velocity jets | Circulating heated air |

| Heating Speed | Faster ramp-up | Slower ramp-up |

| Oven Length | Shorter for same cure time | Longer for same cure time |

| Best For | High line speeds, mixed loads | Heavy parts, varied coatings |

| Footprint | More compact | Larger |

Infrared Ovens: A Footprint and Energy Alternative

Infrared (IR) ovens work differently by using radiant energy instead of moving air. This means the heat is almost instantaneous, allowing for very short oven lengths – often 50-70% shorter than convection ovens. This is a big deal if you’re short on floor space. IR can also be more energy-efficient, especially gas catalytic models, which can offer significant savings compared to convection. They’re great for quick color changes or as a booster to speed up a convection line. However, for very heavy parts or finishes that need a very gradual temperature increase, IR might not be the best primary solution.

- Near-instant heat-up: Elements reach temperature in under a minute.

- Zoned control: Allows for precise heat application to different parts.

- High radiant efficiency: Especially with catalytic models, leading to energy savings.

Hybrid Zones: Combining Technologies for Optimal Results

Sometimes, the best approach is to mix and match. Hybrid systems combine the strengths of different technologies. A common setup is an IR booster zone followed by a convection finishing zone. The IR quickly brings the powder to a gel state, and then the convection zone completes the curing process. This combination can offer the speed and efficiency of IR with the thorough curing capabilities of convection, especially for complex parts or mixed loads. It’s a way to get the best of both worlds, optimizing both cure time and finish quality. Many modern high-throughput lines are moving towards these combined systems to maximize efficiency.

Performance Metrics That Matter

When you’re looking at new ovens, or even trying to figure out if your current one is doing its best, you gotta pay attention to a few key things. These aren’t just random numbers; they tell you a lot about how well your oven is actually working and how much it’s costing you.

Ramp Rate and Its Impact on Oven Length

Think of ramp rate as how fast the oven can get parts up to temperature. A faster ramp rate means you can actually make the oven shorter for the same amount of heating time. This is a big deal because shorter ovens take up less floor space, which is always a win. Direct-impingement ovens are pretty good at this, getting things up to temp quicker than standard convection. It’s all about how fast that hot air hits the part. If you’re trying to speed things up, this is definitely something to look at. We’ve seen lines where just tweaking this made a huge difference in how much they could produce.

Temperature Uniformity for Consistent Quality

This is super important for making sure all your parts come out looking the same. If the temperature isn’t even throughout the oven, some parts might get too much heat, and others not enough. That can mess with the finish, like causing gloss issues or even affecting how well the coating sticks. We’re talking about keeping things within a tight range, like plus or minus 5 degrees Fahrenheit across the whole oven width. That consistency is what keeps customers happy and reduces scrap.

Energy Efficiency and Operational Costs

Nobody wants to waste energy, right? The amount of energy your oven uses per pound of material processed is a direct hit to your bottom line and your environmental footprint. Ovens that use less fuel or electricity to get the job done are obviously better. Sometimes, switching to a different type of oven, like one that uses infrared, can save a ton of energy. It’s worth doing the math to see what makes the most sense for your specific setup and utility costs. Looking at manufacturing metrics can really help you track this over time.

Keeping an eye on these performance numbers isn’t just about bragging rights; it’s about making smart decisions that save you money and make your production line run smoother. It’s the difference between just having an oven and having an oven that’s actually working for you.

Strategic Oven Specification for Manufacturing

Considering Part Characteristics and Finish Chemistry

When you’re picking out an oven, it’s not just about how fast it can go. You really need to think about what you’re actually putting through it. Different parts have different needs, you know? Heavy stuff, like big metal castings, tends to hold onto heat longer. For those, you might want to lean towards a convection oven or maybe a catalytic infrared setup. On the flip side, if you’re dealing with powders like polyesters, infrared can work great. But if you’re using liquid enamels, especially the high-gloss kind, convection might be a better bet because it offers a gentler heating process. It’s all about matching the oven’s capabilities to the specific demands of your product and its coating.

Aligning Oven Choice with Line Speed and Floor Space

Line speed is a big one. If your production line is moving pretty fast, say over 75 feet per minute, you’ll probably need something like direct-impingement or an infrared booster to keep the oven length manageable. Trying to cure things too quickly in a standard convection oven can lead to issues. And let’s not forget about space. If your factory floor is already packed, a long convection tunnel just isn’t going to cut it. In those situations, infrared or a hybrid system often wins because they take up way less room. Choosing the right oven is a decision that impacts your line speed, how much space you need, your energy bills, and the quality of your finish for years to come.

Evaluating Utility Rates and Maintenance Resources

Don’t forget about the ongoing costs and upkeep. What are your local utility rates like? The cost difference between gas and electricity can really change the return on investment, especially if you’re looking at energy-efficient options like catalytic infrared. Also, think about your maintenance team. Do you have people who can handle complex systems, or do you need something more straightforward? Ovens with features like tool-free access for parts and remote diagnostics can make life a lot easier for maintenance staff. It’s smart to consider these practical aspects when making your final choice, ensuring the oven fits not just your production needs but also your operational capabilities. For more on efficient oven designs, check out GAT’s convection process ovens.

The Continuous Oven Advantage

When you’re looking at ways to speed things up in manufacturing, the type of oven you use can make a big difference. While batch ovens have their place, especially for varied parts, continuous ovens really shine when it comes to high-volume production of similar items. They’re designed to keep things moving, which is where a lot of that cycle-time gain comes from.

Batch vs. Continuous Oven Throughput

Think about it this way: a batch oven is like a bus that waits for everyone to get on before it leaves. A continuous oven, on the other hand, is more like a train that keeps moving, picking up and dropping off passengers as it goes. This constant motion means a lot more parts get processed over the same period. For example, if a batch oven takes 7.5 minutes to process 6 parts (including loading and unloading), a continuous oven, even with the same processing time per part, could handle 45 parts in that same timeframe. That’s a massive jump in output. It’s all about keeping the oven full and parts moving.

Minimizing Labor with Automated Processing

One of the big wins with continuous ovens is how much they cut down on manual work. Loading and unloading batch ovens takes time and requires people. With a continuous system, parts are fed in and taken out via a conveyor, often with minimal human interaction. This frees up your operators to do other tasks that add more value to your company. Instead of just moving parts in and out, they can focus on quality control or other critical operations. It’s a smart way to use your workforce more effectively.

Consistent Heating for Identical Parts

With a continuous oven, every part travels through the same path and experiences the same heating profile. This means you get really consistent results, batch after batch, or rather, part after part. If your process involves multiple steps, like pre-heating or controlled cooling, continuous ovens can be designed with different zones to handle these stages within a single machine. This level of control is hard to match with batch operations, especially when you need every single part to come out exactly the same. It’s a key factor in maintaining product quality and reducing scrap. If you’re looking for a more automated and efficient way to handle high-volume thermal processing, a continuous oven might be the right fit for your facility. You can even get custom walk-in ovens designed for specific needs.

Discover the benefits of our continuous ovens! These ovens keep your production line moving smoothly, saving you time and effort. Want to see how they can help your business? Visit our website today to learn more and get a quote!

Wrapping Up: The Power of Direct-Impingement Ovens

So, we saw how switching to direct-impingement ovens really made a difference, cutting down cycle times by a solid 40%. It’s pretty neat how blasting hot air directly at the parts can speed things up so much compared to older methods. This kind of tech is great for places that need to move fast, especially when dealing with different types of metals that can change color if they get too hot for too long. Plus, it seems like these ovens can be a bit cheaper to set up than some other options out there, which is always a plus. It really shows that picking the right oven technology isn’t just a small detail; it can seriously change how efficient your whole operation runs.

Frequently Asked Questions

What exactly is a direct-impingement oven?

Direct-impingement ovens blast hot air directly onto the parts from above and below. Think of it like a super-powered hairdryer aimed right at your product. This makes them heat up much faster and cook coatings more quickly than regular convection ovens, which just circulate warm air around the parts.

When is a direct-impingement oven the best choice?

These ovens are great when you need to process parts really fast, like when your production line is moving at high speeds. They’re also good for jobs where you’re baking different types of metal parts together, because they can heat things up so quickly that it prevents color differences from showing up.

How do direct-impingement ovens compare in size to other ovens?

Compared to standard convection ovens, direct-impingement ovens can often be shorter because they heat things up so efficiently. This means they take up less space on your factory floor. Infrared ovens can also be shorter, but direct-impingement offers a different way to get fast results.

Why is temperature uniformity important in an oven?

Temperature uniformity means how evenly the oven heats all the parts inside. If an oven heats parts unevenly, the coating might not cure right, leading to problems like dull spots or peeling. Direct-impingement ovens, when designed well, can provide very even heating.

What’s the difference between a batch oven and a continuous oven?

A continuous oven runs all the time, with parts moving through it on a conveyor belt. This is very different from a batch oven, where you load a set of parts, run them, and then unload them. Continuous ovens can process many more parts over time with less stopping and starting, often needing less manual labor.

Can one oven bake different kinds of coatings?

Yes, many ovens can handle different types of coatings by simply changing the oven’s settings. You can save different ‘recipes’ for various jobs, like powder coatings or liquid paints, and switch between them easily when needed.