Curing and Drying Ovens How Temperature Uniformity Impacts Film Performance

When you’re making films, the ovens you use for curing and drying really matter. It’s not just about getting things dry; it’s about how the

When you’re making films, the ovens you use for curing and drying really matter. It’s not just about getting things dry; it’s about how the

You know, it’s pretty cool to think about how things are made, especially when it’s right here in our own backyard. Our facility in Fenton,

So, we’re talking about manufacturing efficiency, specifically how to speed things up. A big part of that is the equipment you use, and ovens are

Running a busy job shop means every minute counts. When your paint finishing equipment goes down, so does your productivity and your bottom line. Upgrading

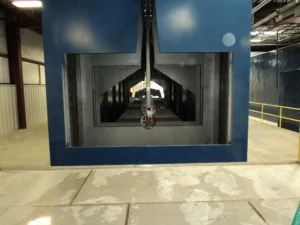

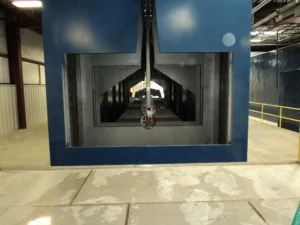

At GAT Finishing Systems, innovation isn’t just a buzzword – it’s the foundation of everything we do. We’re thrilled to announce a groundbreaking leap in

So, you’re looking into powder coating and trying to figure out the whole pretreatment washer thing. It can get a little confusing with all the

Getting a perfect finish with powder coating isn’t just about having good powder. It’s about having the right gear, too. Think of it like baking

Deciding between a convection oven and an infrared oven for your parts can feel like a big choice. Both technologies get the job done, but

In today’s high-mix, just-in-time manufacturing environment, a finishing line can no longer operate in isolation. Engineers and plant managers are under increasing pressure to connect,

When a powder-coat or paint line struggles to hit daily quota, most engineers look first at washers, booths or ovens. Yet the silent speed-killer is

Why this guide? Choosing the right curing technology is one of the highest‑impact decisions you’ll make when bringing powder coating or wet paint in‑house. The

When you’re looking at equipment for industrial pretreatment, like parts washers, you might think stainless steel is the only way to go. It’s tough, right?

Getting the Perfect Powder Coating Finish Starts with the Right System—And the Right Partner At GAT Systems, we do more than just supply equipment—we design

So, you’re a manufacturer, right? And you’re trying to figure out if you should stick with the usual, off-the-shelf equipment or go all-in on something

Industrial Finishing Systems are pretty important in manufacturing. They help make sure products look good and last a long time. It’s not just about painting;

A mediados de los noventa, Larry Rubin, nieto de Herman Neuwirth, fundador de Testrite, y Dan Guirl, nieto de Howard, fundador de GAT Systems, mantuvieron un encuentro crucial.

¿Es el recubrimiento en polvo más duradero que la pintura líquida? ¿De qué tipo de durabilidad estamos hablando? Responderemos a estas preguntas y más en esta entrada del blog.

Se considera que el recubrimiento en polvo es más duradero que la pintura húmeda, más seguro para el medio ambiente y los trabajadores y menos propenso a decolorarse.

Existen dos métodos principales para el acabado del metal: pintura húmeda y recubrimiento en polvo. Ambos tienen sus ventajas y desventajas, pero la industria lleva tiempo inclinándose por el polvo.

El recubrimiento en polvo existe desde la década de 1950, pero sólo últimamente ha ganado reconocimiento como proceso de acabado que destaca por su durabilidad y facilidad de uso.

Colaborar con clientes y proveedores para encontrar soluciones innovadoras en las operaciones de recubrimiento en polvo es el motor del éxito de nuestra empresa.

Sistemas de acabado personalizados

Pericia

Acerca de