In today’s high-mix, just-in-time manufacturing environment, a finishing line can no longer operate in isolation. Engineers and plant managers are under increasing pressure to connect, track, and optimize every stage of production—from pretreatment to final cure—using real-time data. That’s where PLC automation and IIoT (Industrial Internet of Things) come into play.

At Sistemas de acabado GAT, we don’t bolt on controls as an afterthought. We engineer PLC intelligence into every washer, oven, conveyor and booth—giving you a finishing line that’s smart, scalable, and IIoT-ready from day one.

Whether you’re integrating into a plant-wide MES or just starting with local SCADA visibility, this blog breaks down what a truly connected finishing system looks like—and how GAT’s automation-first approach makes it possible.

1 | Why PLC Controls Matter More Than Ever

In traditional finishing lines, human operators managed everything manually: conveyor speeds, zone temperatures, cure times, and even safety checks. Today, those systems are expected to:

- Run multiple product recipes per shift

- Capture part-by-part production data

- Predict maintenance issues before downtime

- Integrate seamlessly with ERP, MES and SCADA layers

- Support remote diagnostics and service

None of this is possible without a programmable logic controller (PLC) infrastructure built with IIoT architecture in mind.

2 | GAT’s Controls Philosophy: Intelligence Built In

Every finishing system GAT delivers is engineered with a centralized or distributed PLC brain, tailored to the line layout, production complexity, and your digital integration goals.

What’s included:

| Feature | What it means | Why it matters |

|---|---|---|

| Ethernet/IP, Profinet or Modbus TCP | Industrial protocol compatibility | Plug-and-play with your plant network |

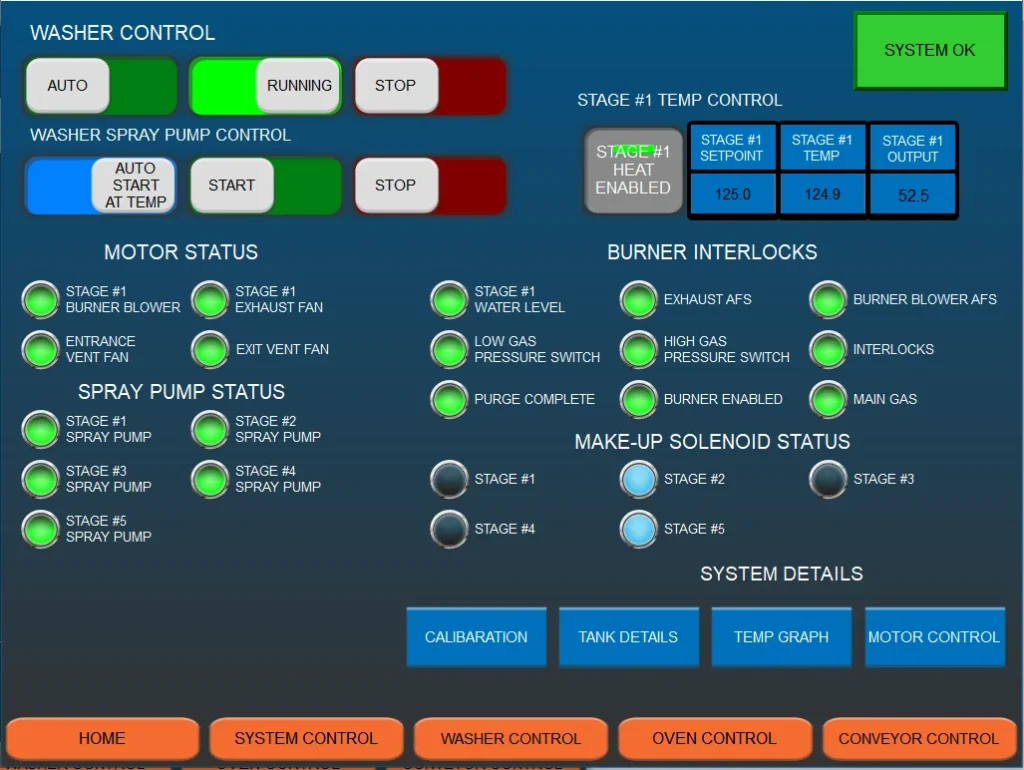

| PLC/HMI integration | Real-time visualization via touchscreen | Operators view alarms, recipes, OEE, and diagnostics at a glance |

| VFD-controlled motors | Variable speed control on ovens, conveyors, fans | Fine-tune takt time and reduce energy use |

| Smart sensors & safety logic | Temperature probes, door interlocks, LFL monitors | NFPA/OSHA compliance, proactive alerts |

| Data logging capability | Event history, cycle count, temp curves | Supports traceability and quality audits |

Whether the line includes an enclosed track conveyor, multi-zone oven, or high-efficiency polypropylene washer, all subsystems report back to a unified controls platform that’s built to scale.

3 | IIoT-Ready from Day One: What That Looks Like

Unlike legacy control panels that require hardware retrofits to connect, GAT systems are designed to be “born connected.”

Practical IIoT features available on GAT lines:

- Live production monitoring via VPN or cloud dashboards

- Predictive maintenance prompts based on cycle count or sensor drift

- Recipe tracking by part number (linked to barcode or RFID input)

- Alarm forwarding to mobile/email

- Secure remote diagnostics (used by GAT’s own support team for faster service)

- Data export to SCADA or MES via CSV, SQL, or direct tag mapping

Example: A GAT customer in the Midwest uses our PLC system to track oven zone temps, conveyor load count, and washer conductivity in real time—then pushes that data to a central plant dashboard for OEE reporting.

4 | The GAT Controls Advantage vs. Piecemeal Integration

If you’re retrofitting a finishing line with controls from multiple OEMs, you’ll likely face:

- Protocol mismatches (e.g., mixing Modbus and Profinet)

- Duplicated HMIs with separate screens for oven, conveyor, washer

- No shared data layer for part tracking

- Delayed commissioning due to wiring and software conflicts

GAT avoids these issues by providing:

- One unified PLC/HMI environment

- Tag-named architecture for easy SCADA handoff

- Standardized alarms and recipes across the system

- Pre-wired, pre-tested panels with labelled terminations

It’s a true plug-and-play, line-wide control architecture—simplifying install, training and long-term support.

5 | Real-World Results: What GAT’s IIoT-Ready Controls Deliver

| Result | GAT customer example |

|---|---|

| Up to 15% faster troubleshooting | Thanks to remote PLC access and real-time alarms forwarded to maintenance teams |

| >98% mechanical uptime | When used with GAT’s recommended PM schedule and diagnostic logging |

| Line-speed optimization | VFD-controlled conveyors that adapt takt time automatically based on part recipe |

| Zero color change delays | Smart powder room interlocks notify teams before reclaim airflow is ready |

| Data-driven energy savings | Thermocouple curves logged and reviewed to minimize burner overrun |

6 | Planning Your Connected Finishing Line: What to Consider

When specifying a finishing system with automation in mind, consider:

✔ Network Integration

Will you need Ethernet/IP, Modbus TCP or another protocol to connect upstream systems?

✔ Recipe Management

Do you run multiple SKUs with unique curing times, color requirements, or line speeds?

✔ Data Retention

Do you need historical trend logs, daily summaries, or part-specific traceability?

✔ Remote Access

Will you support off-site troubleshooting or software updates?

✔ Expansion Readiness

Can your controls scale if you add a part washer, conveyor spur, or extra cure oven?

GAT addresses all of these in the early design stage—not after panels have been built—so you can scale with confidence.

7 | Beyond the PLC: Full Automation Ecosystem from GAT

In addition to oven and conveyor controls, GAT offers automation support for:

- Power-and-free conveyor spur logic

- Zone indexing and accumulation release

- Washer chemical dosing and conductivity tracking

- Powder room fan control and interlocked reclaim

- Booth-to-booth part movement coordination

- NFPA 86 Class A safety integration

You’re not buying a disconnected panel—you’re investing in a fully engineered system with automation as a native feature.

8 | Why Controls Engineers Choose GAT

✅ Custom control panels built in-house—not outsourced

✅ Standard PLC/HMI codebase for easy updates

✅ Future-ready design with IIoT compatibility out of the box

✅ One-stop engineering from layout to PLC to install

9 | Next Steps

If you’re ready to build a finishing line that’s not just functional—but fully connected, adaptable, and intelligent—let’s talk.

Sistemas de acabado GAT will:

✅ Audit your controls requirements

✅ Propose a scalable PLC architecture

✅ Model real-time data flows

✅ Integrate NFPA-compliant safety

✅ Provide a fully documented controls package, including I/O maps, logic flow and network diagrams

Let’s future-proof your finishing line.

Contact GAT Finishing Systems today to request a controls consultation and line automation map—and take the first step toward a finishing system that’s truly Industry 4.0‑ready.