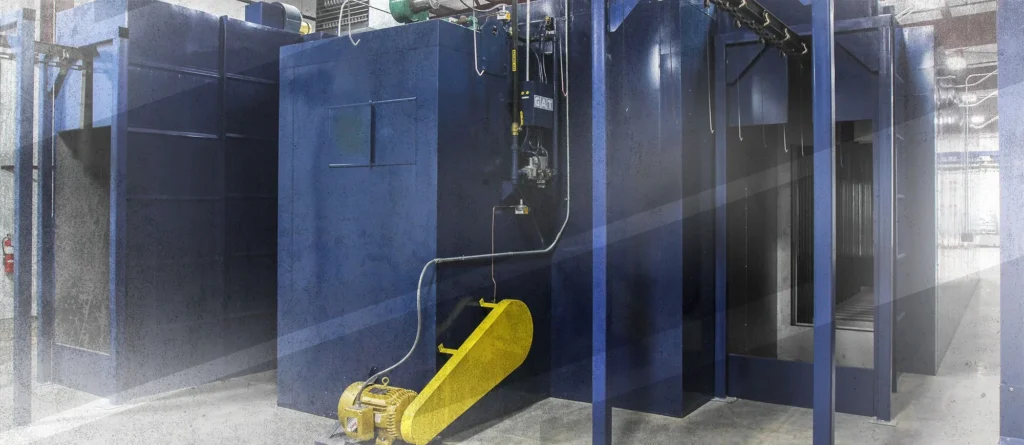

Process Ovens—Continuous Curing & Drying for High‑Throughput Finishing Lines

Whether you need flash‑off, dry‑off or full powder‑coat cure, GAT’s industrial process ovens deliver precise temperature control at conveyor speeds up to 90 fpm. Choose convection, infrared or hybrid heat zones—each built in modular 2‑ft increments to fit your takt time and floor space.

Why Choose a GAT Process Oven?

| Ventaja | Detalle de ingeniería | Production Benefit |

|---|---|---|

| Flujo de aire de impacto directo | High-velocity plenums above & below the part | Faster ramp → shorter oven length |

| Patented Air-Seal Vestibules | Counter-flow curtain keeps heat inside | Up to 15 % fuel savings & cooler aisles |

| 6-Inch Insulated Panels | Mineral-wool core, tongue-&-groove joints | ±5 °F uniformity across the belt |

| Modular Gas Trains | NFPA 86 Class A package burners, leak test valves | Code-ready out of the crate |

| IR Boost / Combo Zones | Short-wave emitters ahead of convection | Cuts cure time for thick sections |

| Tool-Free Access Doors | Full-height swing doors every 6 ft | 5-minute nozzle inspection & cleaning |

Hornos Infrarrojos

Infrared ovens offer a more budget-friendly option that can be added to an existing convection oven setup or to a new oven to allow for an increase in line speed or preheat parts to decrease the chance for a cross contamination. This means less space may be needed for a curing system, and we haven’t even shared the best part yet.

Hornos de convección

Our world-class convection ovens rely on direct air impingement to dry or cure parts more effectively. The “low to high” direct flow of air reduces the oven’s temperature stratification, creating a more energy-efficient and cost-effective solution which produces a high-quality finish in terms of gloss levels and cure matching.

Métricas de rendimiento probadas

- ±5 °F temperature uniformity on 9‑point SAT.

- ≤12‑min powder cure at 400 °F with hybrid IR boost zones.

- Up to 15 % gas savings vs. legacy recirculating ovens (air‑seal vestibules).

Integrate a Complete Line

Process ovens pair seamlessly with arandelas de polipropileno, salas de pintura en polvo y transportadores de vía cerrada for a turnkey finishing system—all designed, built and installed by GAT.

Preguntas frecuentes

Can one oven handle multiple coating chemistries?

Yes—store separate time/temp recipes for polyester, epoxy, urethane or liquid paint.

How long can the oven run without maintenance?

With quarterly filter changes and annual burner tune‑ups, uptime exceeds 98 %.

Do you offer electric convection?

Absolutely—SCR‑controlled heaters available where gas is limited or ESG mandates apply.