When you’re making films, the ovens you use for curing and drying really matter. It’s not just about getting things dry; it’s about how the temperature stays steady inside. If the heat isn’t even, you can end up with all sorts of problems in your final film. We’ll look at why this temperature control is so important and what makes good curing and drying ovens stand out.

Key Takeaways

- Temperature uniformity in curing and drying ovens is vital for consistent film performance, directly impacting defect rates and material integrity.

- Advanced ovens offer precise temperature control, uniform heating distribution, and customizable settings for tailored drying processes.

- Properly managed ramp rates and hold times are essential for optimizing film properties and preventing defects like blistering or cracking.

- Curing and drying ovens are used across many fields, from ceramics and composites to thin films and biomaterials, each with specific needs.

- Modern ovens provide advantages over older methods, including faster processing, better film quality, and reduced contamination, leading to more reliable results.

The Critical Role of Curing and Drying Ovens in Film Performance

Curing and drying ovens are really important for making sure films turn out right. Think about it: if the temperature isn’t the same everywhere inside the oven, you’re going to have problems. Some parts of your film might get too much heat, while others don’t get enough. This unevenness can mess with how the film behaves later on.

Understanding the Impact of Temperature Uniformity

Temperature uniformity is basically about how consistent the heat is across the entire oven space. When it’s not uniform, you get hot spots and cold spots. Hot spots can cause materials to degrade or change in ways you don’t want, like becoming brittle. Cold spots mean the drying or curing process just doesn’t finish properly in those areas. This leads to defects that can really hurt the film’s performance, whether it’s for electronics, coatings, or anything else.

- Uneven drying leads to inconsistent film thickness.

- Hot spots can cause material breakdown.

- Cold spots result in incomplete curing.

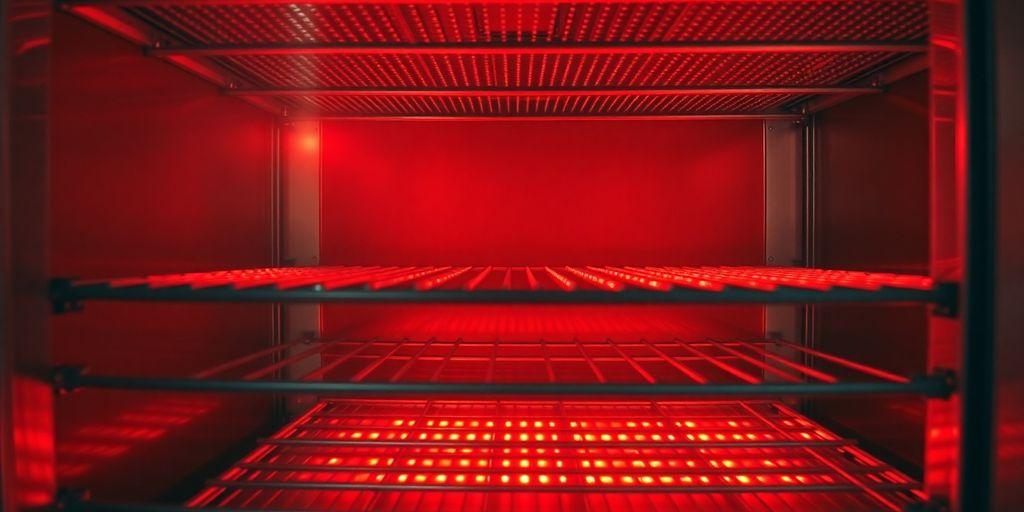

Key Features of Advanced Curing and Drying Ovens

Modern ovens are built to avoid these issues. They often have better insulation, smarter airflow systems, and more precise temperature sensors. These features work together to keep the temperature steady and the same everywhere. This means you get a much better chance of producing high-quality films every time. It’s all about control and consistency, which is what you need when working with sensitive materials.

Benefits of Precise Temperature Control

When you have precise temperature control, you can really dial in the process for whatever film you’re making. This means fewer rejected parts, better product performance, and less wasted material. It’s a big deal for manufacturing efficiency and the overall quality of the final product. Getting this right means your films will do what they’re supposed to do, reliably. You can find out more about how temperature uniformity affects results on pages about oven technology.

Precise temperature control isn’t just a nice-to-have; it’s a requirement for predictable and repeatable film outcomes. Without it, you’re essentially gambling with your production.

Achieving Optimal Film Properties Through Uniform Heating

When you’re working with films, especially in sensitive applications like electronics or advanced coatings, how the heat is applied during curing and drying makes a huge difference. It’s not just about getting the material to the right temperature; it’s about getting all of it there evenly. Think of it like baking a cake – if one side is burning while the other is still raw, you’ve got a problem. The same applies to films. Temperature uniformity is key to making sure your film turns out exactly how you want it, without any weird spots or weak areas.

Minimizing Defects with Consistent Temperature Distribution

Uneven heating in an oven can lead to all sorts of headaches. You might see issues like blistering, cracking, or areas that just don’t cure properly. These aren’t just cosmetic flaws; they can seriously mess with the film’s performance. For instance, a spot that’s underbaked might not have the right electrical conductivity, or a section that overheated could become brittle. Consistent temperature distribution across the entire substrate is what prevents these defects. It means every part of the film experiences the same thermal treatment, leading to a more reliable and predictable outcome. This is especially important when you’re dealing with large batches or complex geometries where maintaining uniformity can be tricky. Getting this right means fewer rejected parts and a better final product.

Enhancing Material Integrity in Thin Film Deposition

In processes like spin coating or dip coating, the film is often still wet and contains solvents when it goes into the oven. If the temperature isn’t uniform, you can run into problems. For example, if one area heats up too fast, it might form a ‘skin’ that traps solvents underneath. When those trapped solvents try to escape later, they can cause bubbles or blisters, which ruins the film’s integrity. Hotplate baking, which heats from the bottom up, can sometimes avoid this ‘skin effect’ because it allows solvents to escape more easily from the bottom before the top seals over. This ‘inside-out’ heating is a big deal for thick films. Achieving uniform heating helps remove solvents efficiently without creating these damaging internal structures, leading to films that are stronger and perform better. It’s all about controlling how those solvents leave the material.

The Science Behind Uniform Heat Transfer

So, how do ovens actually achieve this uniform heating? It’s a mix of good design and smart engineering. Modern ovens use features like precisely controlled airflow, well-placed heating elements, and insulated chambers to keep the temperature steady everywhere. The goal is to minimize temperature gradients – those differences in temperature between different spots in the oven. When you have a stable, even temperature, the heat transfer to your film is consistent. This means the chemical reactions needed for curing happen at the same rate across the entire film, and solvents evaporate predictably. It’s about making sure the energy transfer is balanced. If you’re looking for ovens that excel at this, you might want to check out advanced curing ovens.

Here’s a quick look at common issues and how uniform heating helps:

- Underbaked Film: Often caused by too low a temperature or too short a time. Uniform heating ensures the entire film receives the correct thermal dose.

- Blistering/Cracking: Can happen with rapid heating or uneven temperature. Gradual, uniform heating allows solvents to escape slowly and evenly, preventing trapped gas.

- Non-Uniform Bakes: Directly related to inconsistent temperature distribution. A well-designed oven with uniform heating eliminates hot and cold spots, leading to a consistent bake across the whole batch.

Proper temperature management is not just about hitting a target number; it’s about the consistency of that number throughout the processing space. This consistency is what separates a good film from a flawed one, impacting everything from adhesion to electrical properties.

Customization and Control in Curing and Drying Oven Operations

When you’re working with delicate materials or complex processes, a one-size-fits-all approach just doesn’t cut it. That’s where the customization and control offered by modern curing and drying ovens really shine. It’s all about fine-tuning the environment to get exactly the results you need, every single time.

Tailoring Processes with Programmable Settings

Modern ovens let you set up specific heating schedules, often called profiles. This means you can tell the oven exactly what temperature to reach, how fast to get there (that’s the ramp rate), and how long to hold it at that temperature. This level of control is super important for materials that might degrade if heated too quickly or unevenly. You can save these profiles too, making it easy to repeat a successful process without having to re-enter all the settings.

Optimizing Drying Conditions for Sensitive Materials

Some materials, like certain polymers or biomaterials, are really sensitive to how they’re dried. Too much heat or too fast a drying process can cause them to crack, warp, or lose their intended properties. Ovens with good humidity control can be a lifesaver here. They allow you to remove moisture without completely drying out the material, or you can create a low-humidity environment to efficiently remove water without damaging the sample. Getting the moisture out before curing is key to preventing issues like clumping or premature adhesive hardening in some applications, like DTF printing.

The Importance of Ramp Rates and Hold Times

Think of ramp rates and hold times as the oven’s recipe. The ramp rate is how quickly the temperature changes, and the hold time is how long it stays at a specific temperature. Getting these right is critical. A slow ramp rate might be needed for thick materials to allow heat to penetrate evenly, preventing surface hardening while the inside is still wet. A specific hold time might be necessary for a chemical reaction to complete or for a solvent to fully evaporate. Messing these up can lead to defects like uneven curing or incomplete drying, which directly impacts the final film’s performance.

Applications of Curing and Drying Ovens Across Industries

Curing and drying ovens are workhorses in many manufacturing sectors, playing a vital role in shaping the final properties of materials. It’s not just about baking things; it’s about precise control to get specific results. The way a material is heated and cooled can make or break its performance, whether it’s a delicate electronic component or a robust ceramic part.

Ceramics Processing: From Green Bodies to Fired Products

In ceramics, ovens are used right from the start. After ceramic pieces are shaped, they’re often in a “green” state – meaning they’re unfired and still contain moisture. Drying these green bodies needs to be super even. If one part dries faster than another, you’ll get cracks or warping. This is where uniform temperature distribution in the oven comes in. Later, during firing, the oven’s controlled heating profile is what transforms the fragile green body into a strong, finished ceramic product. Getting this right means the difference between a usable item and scrap.

Polymer Composite Fabrication: Enhancing Mechanical Properties

When making polymer composites, ovens are used to cure the resins that bind everything together. Think of carbon fiber parts or advanced plastics. The oven’s job is to heat the resin evenly, causing it to harden and form a strong, solid matrix. If the heat isn’t uniform, you can end up with weak spots or internal stresses in the composite. This directly impacts how strong and durable the final product will be. Proper curing ensures that the fibers and the resin bond well, leading to better strength and stiffness. It’s a key step for anything that needs to be both light and tough.

Biomaterials Synthesis: Ensuring Scaffold Integrity and Drug Efficacy

In the world of biomaterials, ovens are used for some pretty sensitive tasks. For instance, when creating scaffolds for tissue engineering, the drying and curing processes must be gentle. Ovens help remove solvents or moisture without damaging the delicate structure of the scaffold. For drug delivery systems, ovens might be used to cure coatings that control how a drug is released over time. If the temperature isn’t right, the drug might be released too quickly or not at all. Precise temperature control is absolutely critical for the safety and effectiveness of these medical applications. This is why many of these processes rely on ovens with advanced control systems to manage everything from ramp rates to hold times, making sure the final product performs as intended. The ability to achieve consistent results is paramount when dealing with materials intended for use in the human body.

Troubleshooting Common Film Defects with Curing and Drying Ovens

Addressing Blistering and Cracking Through Temperature Management

Film blistering and cracking are common headaches in the curing and drying process, and they often point to issues with how temperature is being managed. Think of it like trying to dry a thick cake too quickly in a super hot oven – the outside gets done (or even burns) while the inside is still gooey. In films, this can happen if the surface heats up too fast, forming a ‘skin’ that traps solvents. As these solvents try to escape later, they push outwards, causing blisters or cracks. This is especially true for thicker films or certain materials like polyimides. A key fix here is to adjust the heating profile. Instead of a sudden blast of heat, a gentler, more gradual warm-up can help solvents escape evenly. Sometimes, reducing the overall temperature and extending the bake time can also prevent this skin formation. It’s all about finding that balance so the entire film cures properly, not just the surface.

Resolving Non-Uniform Bakes with Precise Control

When you end up with a non-uniform bake, it means parts of your film have been treated differently than others. This can be caused by a few things. Maybe the oven’s internal temperature isn’t consistent across the chamber, or perhaps something is blocking airflow. Another culprit could be how the substrate is placed or if the oven door was left open too long during the process, letting heat escape unevenly. For instance, if the exhaust lid is raised too much, it can disrupt the stable temperature needed for a good bake. Fixing this often involves checking the oven’s calibration and ensuring proper airflow. If you’re using a hotplate, make sure the surface is clean and free of contaminants that could create hot or cold spots. Sometimes, simply adjusting the position of the substrate or ensuring the exhaust is properly managed can make a big difference in achieving a consistent cure across the entire film. Getting the right bake temperature and time is really important here.

The Impact of Bake Time and Temperature Balance

Getting the bake time and temperature just right is like a delicate dance. Too much heat for too little time, and you might underbake the film, leaving solvents trapped or not achieving full cure. Too little heat for too long, and you risk overbaking, which can degrade the film’s properties. It’s a constant balancing act. For example, if a film is showing signs of being underbaked, it might mean the temperature was too low or the time was too short. The solution? Increase the temperature slightly or extend the bake duration. Conversely, if you see signs of overbaking, you’d want to decrease the temperature or shorten the time. It’s also worth noting that the initial warm-up phase matters. If the substrate heats up too quickly, it can lead to issues like blistering, as mentioned earlier. Using techniques like a proximity bake can help preheat the substrate more gently. Ultimately, understanding how these two factors interact is key to avoiding common film defects and achieving the desired film performance.

Advantages of Modern Curing and Drying Ovens Over Conventional Methods

When you look at how curing and drying ovens have changed, it’s pretty wild. The old ways of doing things, they just couldn’t keep up with what we need today. Modern ovens are a whole different ballgame, offering some serious upgrades.

Reduced Bake Times and Increased Throughput

One of the biggest wins with newer ovens is how much faster they can get the job done. Instead of waiting hours, you might be looking at minutes for certain processes. This isn’t just about saving time; it means you can process more parts in the same amount of time. Think about a manufacturing line – speeding up the oven stage means you can push more product out the door. It’s a direct boost to productivity and can really change the economics of a production run. For example, some advanced systems use a combination of convection and infrared heat, which really speeds up the curing process for powders, leading to better oven performance metrics.

Superior Film Quality and Reproducibility

Remember those days when you’d get a batch of parts, and some would be perfect while others had issues? Modern ovens, with their tight temperature control and uniform heating, largely put an end to that. They create a much more consistent environment inside. This means the film you’re curing or drying behaves the same way, no matter where it is in the oven. You get fewer defects, better adhesion, and the final product is just plain better. Plus, because the process is so repeatable, you can trust that tomorrow’s batch will be just as good as today’s. It takes a lot of the guesswork out of the equation.

Minimizing Particle Contamination for Cleaner Processes

Cleanliness is a big deal, especially when you’re dealing with sensitive materials or high-tech films. Older ovens could sometimes be a source of contamination, with dust or particles getting blown around. Newer designs often incorporate better filtration systems and airflow management. This helps keep the inside of the oven much cleaner, which is vital for preventing tiny specks from ruining a delicate film or coating. It’s a subtle but important advantage that contributes to overall product integrity.

Modern ovens offer big improvements over older drying and curing methods. They work faster, use less energy, and give you more control over the process, leading to better results. If you’re looking to upgrade your equipment and see these benefits for yourself, check out our range of advanced ovens on our website.

Wrapping Up: Why Oven Uniformity Matters for Your Films

So, we’ve talked a lot about how ovens work and why getting the temperature just right is a big deal, especially when you’re making films. It’s not just about getting things dry; it’s about making sure the whole batch comes out the same. If your oven has hot spots or the temperature swings too much, you’ll end up with films that aren’t quite right. This can mean anything from weak spots to uneven performance later on. Using ovens that keep a steady, even temperature helps avoid these problems, leading to better quality films every time. It really comes down to having the right tool for the job to get consistent results.

Frequently Asked Questions

Why is it important for the oven temperature to be the same everywhere inside?

Think of temperature uniformity like making sure every cookie on a baking sheet gets cooked evenly. If the oven is too hot in one spot and too cool in another, some cookies might burn while others are still doughy. For films, this means if the oven’s temperature isn’t the same everywhere, parts of the film might dry too fast or too slow, causing problems like cracks or weak spots. Keeping the temperature steady and the same all around helps the film dry and cure just right.

How does even heating help make better quality films?

When you’re making a film, especially a thin one, even small changes in how hot it gets can mess things up. If one part of the film gets too much heat, it might get brittle. If another part doesn’t get enough, it might not become strong enough. Consistent heat makes sure the whole film turns out strong and works the way it’s supposed to, like for electronics or special coatings.

Can I control how the oven heats and cools the film?

Imagine you’re baking a cake. You need to set the oven to the right temperature and leave it in for the right amount of time. It’s the same for films. You can tell the oven exactly what temperature to be and how long to stay there. You can also set how fast it heats up or cools down. This helps you dry or ‘bake’ the film perfectly, making sure it doesn’t get damaged and has all the good qualities you want.

What are some examples of how these ovens are used in different industries?

Yes, ovens are used in lots of different jobs! For making ceramics, they help dry them evenly so they don’t crack before being fired. For making strong plastic parts with stuff like carbon fiber mixed in, ovens help the plastic harden correctly. And for making tiny medical parts or things that deliver medicine, ovens help make sure these materials are made safely and work as intended.

How can oven settings help fix problems like cracked or bubbly films?

Sometimes films can get bubbles or cracks, or they might not dry evenly. This often happens if the oven’s temperature is wrong or the time is off. For example, if the oven heats up too fast, it can create a hard ‘skin’ on the film that traps moisture inside, causing bubbles. By carefully adjusting the oven’s temperature and how long the film stays inside, you can fix these problems and get a smooth, strong film.

What makes modern ovens better than older ones for making films?

Older ovens were sometimes slow and could let dust or tiny particles get into the clean environment needed for making films. Modern ovens are much better. They can dry films faster, give you more consistent results every time, and are designed to keep the air cleaner, which means fewer tiny specks can land on your film and cause defects.