Deciding between a convection oven and an infrared oven for your parts can feel like a big choice. Both technologies get the job done, but they do it in pretty different ways. Think of it like choosing between a fan heater and a heat lamp. One circulates warm air, while the other beams heat directly. This article breaks down the main differences to help you figure out which type of oven will work best for what you need to cure.

Key Takeaways

- Convection ovens use circulating hot air, which is great for heating complex shapes evenly because the air reaches all surfaces. Infrared ovens heat directly with radiant energy, working best on flatter items but needing conduction to reach hidden spots.

- Infrared ovens are typically faster to heat up and respond to changes, using less energy because they target the product directly. Convection ovens take longer to adjust temperatures and can waste energy when not running at full capacity.

- Infrared systems are generally more compact and require less maintenance than convection ovens, which often need more upkeep on fans and filters.

- For mixed batches where parts vary in size or mass, convection ovens offer more consistent heating since they don’t heat parts at different rates. Infrared ovens require grouping similar parts together for even results.

- Hybrid systems that combine both infrared and convection heating can offer the best of both worlds, providing rapid heating from infrared and uniform temperature distribution from convection.

Understanding Convection Ovens vs. Infrared Ovens

When you’re looking to cure parts, you’ve got a couple of main technologies to consider: convection ovens and infrared ovens. They both get the job done, but they go about it in pretty different ways, and understanding those differences is key to picking the right one for your needs.

How Infrared Ovens Operate

Infrared ovens work by using electromagnetic radiation, specifically wavelengths that we can’t see. Instead of heating up the air around your parts like a regular oven, infrared systems send out heat directly to the surface of whatever you put inside. Think of it like the sun’s rays warming your skin – the energy goes straight to the object. This is done using special reflectors that focus the heat. Because the energy is absorbed directly, it can heat things up a lot faster, which is great for cutting down on curing or drying times. This direct heating method also means less energy is wasted heating up the surrounding air, making them pretty efficient. Many industrial processes, like powder coating and paint drying, rely on this targeted heat. You can find more details on radiant heat applications in various industries.

The Role of Radiant Heat

Radiant heat is the star player in infrared ovens. This heat is generated by converting electrical or gas energy into infrared waves. These waves then travel through the air and release their energy when they hit a surface, causing the molecules in that surface to vibrate and get hotter. It doesn’t really matter what the air temperature is; the heat goes straight to the object. This is why infrared ovens are so good at heating up specific materials quickly, including moisture within those materials. It’s a clean process too, with no combustion byproducts or need to recirculate air, which is a big plus for sensitive applications.

Convection Heating Principles

Convection ovens, on the other hand, rely on circulating hot air. A fan blows hot air all around the oven cavity, and this moving air transfers heat to your parts. It’s a bit like a very strong, hot breeze. This method is really good at making sure all surfaces of a part get heated evenly, especially if you have complex shapes or three-dimensional geometries. The constant movement of air helps to equalize the temperature throughout the oven. However, it does take time for the air to heat up and then transfer that heat to the part, especially if the part is dense or a good conductor of heat. This slower heat transfer means longer process times compared to infrared, and the fans can also create noise and move dust around, which might not be ideal for very clean environments.

Heat Transfer Dynamics and Part Geometry

When you’re trying to figure out the best way to cure your parts, how the heat actually gets to them is a big deal. It’s not just about how hot the oven gets, but how that heat moves and interacts with the shape and material of what you’re trying to cure. This is where convection and infrared ovens really show their differences.

Convection’s Advantage with Complex Geometries

Convection ovens work by circulating hot air. Think of it like a really powerful fan blowing warm air all around your parts. This is great for parts with lots of nooks, crannies, or internal spaces. Because the air can get everywhere, it tends to heat all surfaces to a similar temperature. This makes it a solid choice when you have intricate shapes that might otherwise have areas that don’t get enough heat. The consistent movement of air helps to even out the temperature across the entire part, which is a big plus for getting a uniform cure.

Infrared’s Line-of-Sight Heating

Infrared (IR) ovens, on the other hand, work differently. They use electromagnetic waves, kind of like light, to transfer heat directly to the surface of the part. This is often called radiant heat. The energy travels in straight lines from the emitter to the part. This means that the parts facing the IR emitters will heat up quickly. However, if a part has a complex shape, areas that are hidden or not directly facing the emitters might not get heated as effectively. It’s a bit like trying to warm yourself with a campfire – you only get warm on the side facing the flames.

Addressing Hidden Areas with Infrared

So, how do you deal with those tricky hidden areas when using IR? Well, it’s not always a complete roadblock. Metals, for instance, are really good at conducting heat. So, even if an area isn’t directly hit by the IR waves, the heat can travel through the metal to reach it. This is called conduction. To make this work even better, some IR ovens have a “booster” section at the start to quickly heat the part, and then a “soak” section to give the heat time to spread through the material. This can actually make the process faster than using convection alone. For applications where direct line-of-sight heating is a problem, combining IR with convection in a hybrid system can be a smart move, giving you the best of both worlds. You can learn more about different oven types for coil coating lines to see how these technologies are applied.

Ultimately, the geometry of your part is a major factor in deciding which heating technology will give you the most consistent and effective cure.

Operational Efficiency and Control

When you’re looking at ovens for your parts, how fast they work and how well you can control them really matters. It’s not just about getting things hot; it’s about doing it smartly and consistently.

Energy Efficiency Comparison

Infrared ovens tend to be quite good with energy. They convert a lot of electricity directly into heat that goes right to your parts. This means less wasted energy heating up the air inside the oven. Convection ovens, on the other hand, heat the air first, and that hot air then heats your parts. While they’ve gotten better, there’s often more energy lost to the surroundings or just heating up the oven cavity itself. For a lot of applications, especially those needing quick heat-up, infrared can be the more efficient choice. It’s like shining a flashlight directly on an object versus heating the whole room to warm that object.

Reaction Times and Process Changes

This is where infrared really shines. Because it’s direct heat, infrared elements can turn on and off almost instantly. This means if you need to change the temperature or adjust the heating profile for different parts, the oven responds right away. Convection ovens have to heat up the air and then the fans have to circulate it, so there’s a delay. If your production line needs to switch between different types of parts or different curing steps frequently, the rapid response of an infrared system can save a lot of time and improve your overall throughput. Direct impingement ovens can reach target temperatures in under a minute, which is a big deal for shorter curing tunnels compared to convection ovens.

Temperature Control Capabilities

Both types of ovens can offer good temperature control, but they do it differently. Infrared ovens often use precise digital controllers and can even have different zones that you can control independently. This means you can focus heat where it’s needed most, which is great for parts with varying thicknesses or materials. Convection ovens rely on circulating hot air, and while they can be very uniform, achieving very specific, localized heat can be trickier. For processes that need really tight temperature tolerances, like certain electronics or specialized coatings, the zonal control of infrared can be a big advantage. Many advanced systems use PLCs and HMIs for programmable heating and monitoring, which really helps with consistency and safety, especially in regulated industries.

Precise temperature control is a big deal for product quality. Whether you’re drying paint or curing a coating, getting the heat just right, every time, makes a difference. Infrared systems often give you more direct control over where that heat goes.

Here’s a quick look at some general differences:

| Feature | Infrared Oven | Convection Oven |

| Energy Transfer | Direct radiant heat to part | Indirect heat via circulating hot air |

| Heat-Up Time | Very fast (seconds to minutes) | Slower (minutes) |

| Response to Changes | Near-instantaneous | Delayed |

| Zonal Control | Typically excellent, easy to implement | More challenging, relies on airflow management |

| Energy Efficiency | Generally higher due to direct heating | Can be lower due to heating air and cavity |

| Noise Level | Typically quieter (fewer moving parts) | Can be noisier due to fans |

| Maintenance | Often simpler, fewer mechanical components | More complex, fans and motors require upkeep |

Design and Application Considerations

When you’re figuring out which oven technology to go with, it’s not just about how fast it heats or how evenly it spreads the warmth. You’ve also got to think about where it’s going to live in your shop and what exactly you’ll be putting in it. These practical aspects can really make or break your process.

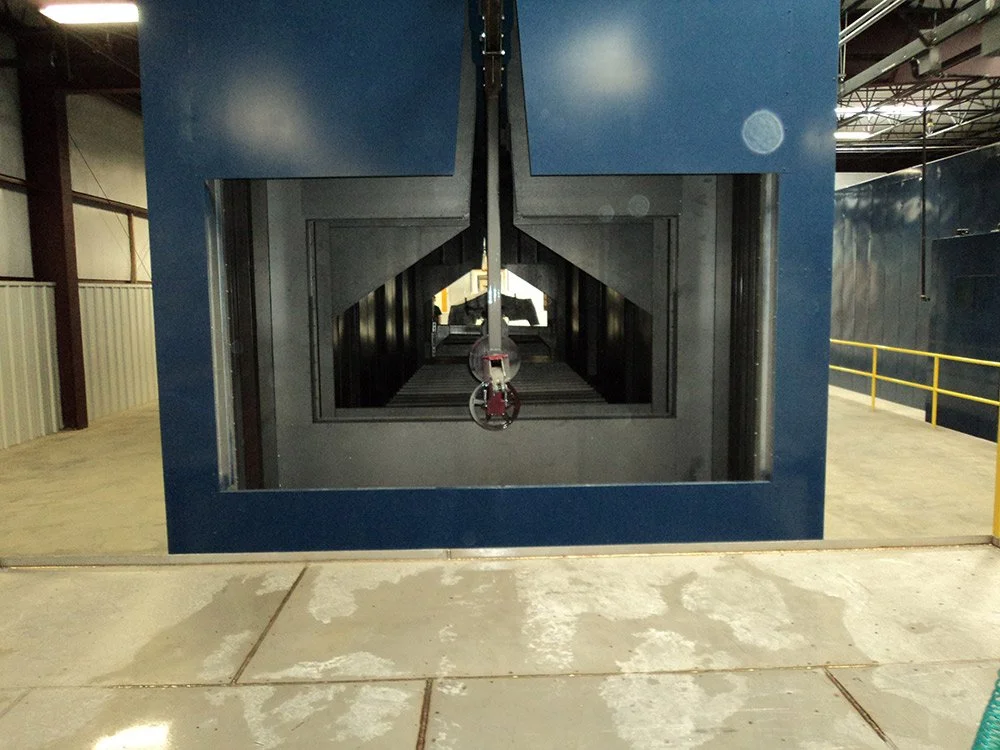

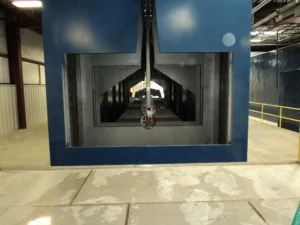

Footprint and Space Requirements

Convection ovens, with their need for circulating large volumes of air, often require more substantial housing and ventilation systems. This means they can take up a bigger chunk of your valuable floor space. Infrared ovens, on the other hand, can sometimes be more compact. They don’t need the same kind of massive airflow, which can simplify their installation and reduce the overall footprint. It’s a bit like comparing a big, airy room to a more focused heat lamp setup – both do the job, but they need different amounts of real estate.

Product Testing and Oven Design

Before you commit, it’s smart to do some testing. The specific properties of your parts, like their size, shape, and what they’re made of, will heavily influence how well each oven type works. For instance, if you’re dealing with flat surfaces, infrared might be a great fit. But if you have complex shapes with nooks and crannies, you might need to think about how the heat will reach everywhere. Sometimes, custom oven designs are necessary to get the best results for unique products. It’s always a good idea to check out commercial oven options to see what’s out there.

Mixed Batches and Mass Considerations

What happens when you have different types of parts or varying quantities to cure at the same time? This is where things can get tricky. Convection ovens, because they heat the entire oven cavity, can sometimes handle mixed batches more easily, as long as the temperature requirements aren’t wildly different. Infrared ovens, however, are more sensitive to the specific heat absorption of each part. If you’re curing a mix of materials with very different heat needs, you might end up with some parts over-cured while others are under-cured. You also have to consider the thermal mass of your parts; heavier items will take longer to heat up, and you need an oven that can accommodate that.

The choice between convection and infrared isn’t always black and white. Often, the best solution involves understanding the limitations of each and how they might interact with your specific production needs and facility layout. Don’t be afraid to explore hybrid options if a single technology doesn’t quite fit the bill.

Maintenance and Environmental Factors

When you’re looking at convection versus infrared ovens, thinking about how much work they’ll need to keep running smoothly and how they fit into your workspace is pretty important. It’s not just about the heating part; it’s about the whole package.

Maintenance Requirements for Each Technology

Both types of ovens need regular attention, but the specifics can differ. Infrared ovens often have elements that might need cleaning or eventual replacement. Think of them like light bulbs – they have a lifespan. Keeping the reflectors clean is also key for efficient heating. Convection ovens, on the other hand, usually have fans and filters that need checking. Dust and debris can build up, affecting airflow and, consequently, how evenly things heat up. Regular cleaning and component checks are vital for both to prevent performance drops.

Here’s a quick rundown:

- Infrared Ovens:

- Clean emitters and reflectors.

- Check for debris buildup on protective covers.

- Inspect and replace worn-out heating elements.

- Convection Ovens:

- Clean or replace air filters.

- Ensure fan blades are free of obstructions.

- Check ductwork for any blockages.

Noise Levels and Operational Environment

This is where things can get a bit different. Convection ovens, with their fans constantly moving air, can sometimes be a bit noisy. This might be a factor if your workspace is sensitive to sound or if you have people working very close by. Infrared ovens, especially electric ones, tend to be quieter because they don’t rely on moving air in the same way. They also often require less ventilation since they don’t produce combustion byproducts, which can make them a good choice for cleaner environments. If you’re looking for a quieter operation, an infrared setup might be more suitable. You can find more information on oven types for coil coating that touches on these aspects.

Suitability for Clean Applications

For industries where a clean environment is a must, like electronics manufacturing or certain food processing applications, the choice becomes clearer. Infrared ovens, particularly electric models, often have an edge here. Because they don’t rely on circulating air to transfer heat, they can be designed to minimize air movement within the oven chamber. This means less chance of airborne contaminants being blown around and settling on your parts. Convection ovens, by their nature, move air, which can be a concern in ultra-clean settings. However, advanced convection systems can incorporate sophisticated filtration to mitigate this. It really depends on how strict your cleanroom requirements are.

Hybrid Solutions for Optimal Curing

Sometimes, neither a pure convection nor a pure infrared oven is the perfect fit for every job. That’s where hybrid systems come in. These setups combine the strengths of both technologies to give you a more versatile and effective curing process. Think of it as getting the best of both worlds.

Combining Infrared and Convection Heating

Hybrid ovens typically use infrared emitters for the initial, rapid heating of the part and the coating. This gets things up to temperature quickly. Then, convection heating takes over to provide a more uniform and stable temperature throughout the curing cycle. This combination is great for parts with varying thicknesses or complex shapes where you need both speed and even heat distribution. It helps avoid issues like over-curing on thin spots or under-curing on thicker areas. For instance, a system might use IR to quickly bring the part up to a certain temperature, and then use convection to hold it there for the required dwell time, ensuring a complete and consistent cure. This approach can significantly improve the quality of the finished product, especially when dealing with different types of parts or coatings.

Benefits of Hybrid Systems

So, what are the big advantages of going hybrid? For starters, you get faster cure times compared to convection-only systems because the IR jumpstarts the process. You also get better temperature uniformity, which is a big win for part quality, especially when you have mixed batches. This means fewer rejects and a more consistent finish across all your products. Plus, the flexibility to adjust the IR and convection stages independently allows for fine-tuning the process for specific coatings and part geometries. This adaptability is key in today’s manufacturing environment where product lines can change frequently. Many manufacturers find that these systems offer a more forgiving cure window, reducing the risk of over-baking or under-curing, which is a common concern with IR-only setups. You can find more information on different oven types at GAT Systems.

Achieving Uniform Heating with Combined Technologies

Achieving truly uniform heating, especially with parts that have varying mass or complex geometries, is where hybrid systems really shine. The IR emitters can be zoned and controlled to deliver more energy to thicker sections or areas that act as heat sinks, like weld seams or doubled-up metal. Meanwhile, the convection component provides a consistent ambient temperature around the entire part, filling in any gaps that line-of-sight heating might miss. This dual approach helps to overcome the limitations of each individual technology. For example, if you’re curing a part that has both thin and thick sections, the IR can quickly heat the thin areas without overcooking them, while the convection ensures the thicker areas receive enough sustained heat to cure properly. This careful balance leads to a more robust and reliable curing process, minimizing defects and maximizing the quality of your coated parts.

Discover how combining different curing methods can lead to the best results for your products. Our advanced systems offer flexibility and efficiency, ensuring a perfect finish every time. Want to learn more about creating your ideal curing setup? Visit our website today to explore our solutions!

Making the Right Choice for Your Parts

So, when it comes down to it, picking between convection and infrared ovens really depends on what you’re trying to achieve. Convection is a solid, reliable choice, especially for those tricky 3D shapes where even heating is key. It’s also pretty straightforward to use, needing less upfront testing. Infrared, on the other hand, shines when you need speed and efficiency, particularly for flatter parts, and it takes up way less space. It’s also more energy-conscious and can react to changes much faster. Many folks are finding that combining the two technologies, maybe with an infrared booster followed by convection, gives you the best of both worlds – fast initial heating and then that even, thorough cure. Think about your specific parts, your production speed needs, and the space you have available. That’ll help you figure out which heating method, or maybe a mix of both, is the right fit for your operation.

Frequently Asked Questions

How do convection and infrared ovens heat things differently?

Convection ovens use fans to blow hot air all around your parts. This is great for making sure everything gets heated evenly, especially if your parts have lots of nooks and crannies. Infrared ovens, on the other hand, use special lights that send out heat waves directly to the parts. Think of it like standing in the sun – you feel the heat right on your skin.

What are the main benefits of infrared ovens compared to convection ovens?

Infrared ovens are often quicker to heat up and can be more energy-efficient because they focus the heat directly onto the object. They also tend to be smaller and quieter since they don’t need big fans. Convection ovens, while great for even heating, can take longer to warm up and might use more energy because they heat the air inside the whole oven.

Which type of oven is better for heating oddly shaped or complex parts?

For parts with complex shapes, like sculptures or engine parts with many curves and openings, convection ovens are usually better. The circulating hot air can reach all surfaces equally. Infrared ovens work best on flatter surfaces or parts where the heat can directly reach all sides. For tricky shapes, infrared might only heat the parts it can ‘see,’ and the rest relies on heat moving through the material, which can be slower.

Can you use both convection and infrared heating together?

Yes, many companies are now combining both! They might use an infrared ‘booster’ at the start to quickly heat the part, and then a convection oven to make sure everything is heated evenly. This way, you get the fast heating of infrared and the uniform coverage of convection, leading to the best results.

What kind of maintenance do these ovens typically need?

Infrared ovens usually need less upkeep. You might need to change the heat emitters or clean filters now and then. Convection ovens, with their fans and filters, often require more regular maintenance, sometimes needing a full breakdown for cleaning.

How do the ovens handle heating different types of parts at the same time?

If you’re heating different kinds of parts at the same time, convection ovens are more forgiving. They heat the air, so even if parts have different sizes or materials, they’ll eventually reach the same oven temperature. With infrared, parts heat up based on how much heat they absorb directly. So, if you have a mix of big and small or dense and light parts in an infrared oven, they might not all get heated the same way. It’s best to group similar parts together.